This is one low-key company on social media, suggested by @coderush3 😊

About the Company

Established in 1982, Diffusion Engineers Limited (DEL), Mcap 1400 Cr, is a company that provides specialised engineering solutions primarily for heavy industries (cement, steel or mining).

Their core business revolves around “superconditioning”, which involves enhancing the durability and extending the lifespan of industrial equipment. This helps their customers keep their large machines and industrial plants running more efficiently and for longer periods, which is crucial for their profitability.

Key Management

- Prashant Garg (Chairman and Managing Director):

He has been associated with the company since 2003, bringing approximately 20 years of experience in the industry. He is responsible for the company’s day-to-day operations, new product development, and technology upgrades in production processes.

He holds 27.91% of equity shares in the company.

Remuneration: 240 Lakhs in FY25

- Abhishek Mehta (Chief Financial Officer): Seasoned finance professional with 20+ years of experience leading strategic finance, capital allocation, and business transformation in the heavy engineering and manufacturing sector.

Remuneration: 18 Lakhs in FY25

Business Model – How do they make money?

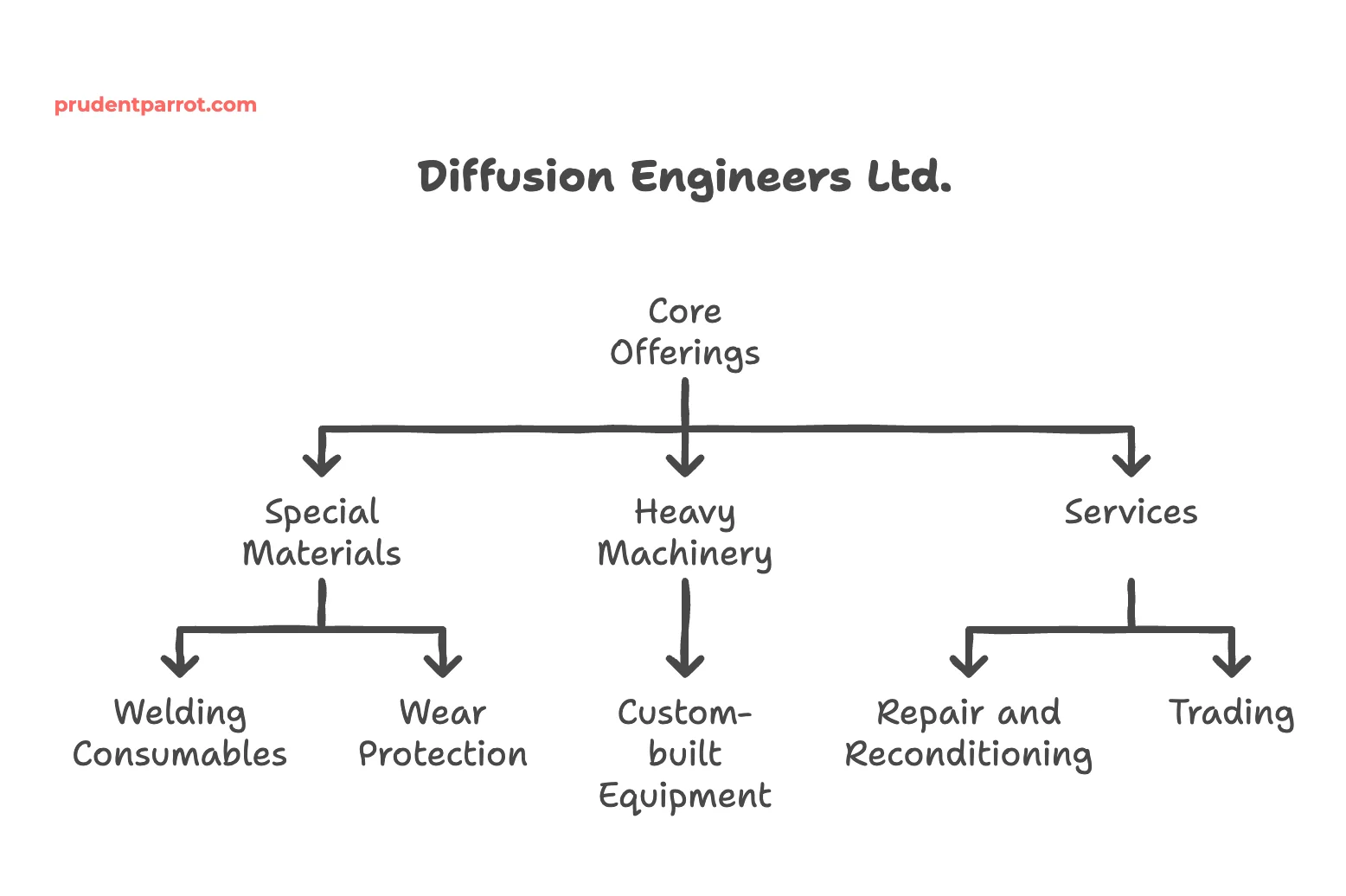

Revenue Streams of DEL:

- Special Materials

- Welding Consumables: Special-purpose electrodes, flux-cored wires.

- Wear Protection: Wear plates and wear parts for high-impact and high-temperature conditions.

- Heavy Machinery

- Custom-built engineering equipment for industries like cement, steel, power, and sugar.

- Machines range up to 500 tons in weight.

- Services

- Repair and reconditioning of heavy machinery, both in-house and on-site.

- Critical breakdown repair and preventive maintenance.

- Trading of anti-wear powders and welding/cutting machinery.

Now, let’s look at the details of their product categories – Welding Consumables, Wear Protection and Heavy Engineering Equipment.

1. Welding Consumables:

2. Wear Plates/Parts

3. Heavy Engineering Equipment

Raw Material Components:

- Ferro alloys (primary input)

- Powdered metals: Chromium, Nickel, Molybdenum, Manganese

- Steel plates and metal wires

- Various specialised alloys

Sourcing of Raw Materials:

1. For core inputs like nickel, chromium, and high-alloy steels, DEL employs a multi-vendor sourcing strategy to mitigate price volatility.

2. To address supply-chain disruptions, they are localising select grades through Indian ferro-alloy suppliers. This implies that ferro alloys are primarily sourced from external suppliers rather than manufactured in-house.

3. Specialised powdered alloys are not manufactured directly by DEL itself, but through a related entity – LSN Diffusion Limited, in the UK

4. Upcoming: DEL is in the process of setting up a new strip slitting plant that will be used to manufacture steel strips, which are a critical raw material for their flux-cored wires. This facility is part of a new manufacturing complex in Nagpur and is slated to commence operations within the current financial year, FY26.

Note: Raw material contributes around 50% of the expenses

Seasonality of the business

To read the full article, please subscribe to PRUDENT Ideas Membership!

Disclaimer: This article is provided for informational purposes only and should not be considered as an investment advice

Also Read: